Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Spherical roller bearings are designed to withstand high loads – and sealed versions have the additional advantage of extending service life even further, says David Oliver, Channel and Platform Development Manager, Bearings and Units at SKF.

Although they were first launched nearly a century ago, SKF spherical roller bearings are remarkably robust and reliable – due largely to the many upgrades they have undergone.

The latest range of SKF Explorer spherical roller bearings, for example, can accommodate very heavy radial and axial loads in applications that are prone to misalignment or shaft deflection. These include: gearboxes, pinion gears and pumps; fans and blowers; mining and construction equipment; textile machinery; and many others.

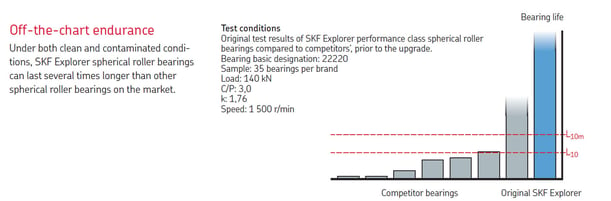

Recent upgrades to the series – including the use of high-quality steel and a new heat treatment process – have helped to double their service life in comparison with previous generations. At the same time, they will last several times longer than competitor bearings under typical heavy-duty conditions.

This longer service life is especially relevant under difficult operating conditions where bearings are subjected to contamination or poor lubrication.

The bearings are fully interchangeable with previously specified standard SKF spherical roller bearings of the same size, and they are also available in custom designs – and as either open or sealed variants.

The range of SKF Explorer spherical roller bearings with integral seals, which lengthens bearing service life in highly contaminated environments, is now available in a greater variety of sizes. Sealed SKF Explorer spherical roller bearings are available in diameters ranging from 25mm to 460mm (sizes 05 to 92). For smaller sizes – up to 120mm – the sealed bearing is slightly wider than its open equivalent.

They are pre-lubricated with specially formulated grease, and protected with highly effective contact seals. This resists the ingress of contaminants that might otherwise adversely affect the bearing and lubricant or cause premature failure. In a typically contaminated environment, a sealed bearing has a rating life of up to four times that of an open bearing. This extended lifetime leads to more productive and profitable operation.

The enhanced cleanliness within a sealed bearing – in comparison with an open bearing – offers the potential, when operating in a contaminated environment, to downsize without reducing either service life or performance. For example, a size 20 (100mm diameter) sealed spherical roller bearing could potentially have the same SKF rating life as the same series size 26 (130mm diameter) equivalent bearing without seals. In both cases, the calculation considered standard SKF bearing grease, an equivalent load of 90kN and a rotation speed of 500 revolutions/minute was used.

With a new design that can halve seal friction, small size sealed SKF spherical roller bearings reduce operating temperature by up to 20°C, which allows the limiting speed rating to be doubled. This extends the number of applications that can benefit from these bearings.

In many applications, the sealed bearings can be considered lubricated for life, which completely eliminates the relubrication interval. This significantly reduces the cost to buy, apply and dispose of grease. Such a reduction in maintenance costs will, in many cases, reduce the total cost of ownership of an application.

Overall, the main benefits of sealed spherical roller bearings are: a significant reduction in maintenance needs; lower grease consumption and environmental impact; substantial improvement in uptime; and, improved worker safety.

Spherical roller bearings also play an integral part in the SKF Three Barrier Solution – which is used for the harshest operating conditions. It comprises a standard SKF housing, a sealed spherical roller bearing and labyrinth seals. Together, this combination of products helps to extend service life without complicated and expensive sealing arrangements. By protecting the bearing during assembly and operation, it optimises bearing service life while requiring minimal maintenance.

If accessibility makes it difficult – or impossible – to relubricate a spherical roller bearing, Solid Oil is an alternative solution. Solid Oil is an oil-saturated polymer matrix that fills the entire free space in the bearing, encapsulating and protecting both the rolling elements and cage from low to moderate levels of contamination. Enough oil is released form the polymer matrix to lubricate the bearing when in operation with any excess being reabsorbed. For highly contaminated environments, sealed spherical roller bearings can also be supplied with Solid Oil. Bearings with Solid Oil can operate at temperatures up to 85°C (185°F) and at low speeds. Almost any size can be supplied as a Solid Oil bearing.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000