Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

If you sometimes feel your customers want to have their cake and eat it, in several different flavours and delivered next day… you’d be right. They want more diverse products. Delivered more quickly. In smaller quantities. And at lower prices. But in the highly competitive, ever-accelerating manufacturing sector, your only option is to keep pace and keep your customers satisfied. So an untapped source of increased productivity in your plant could help.

As production machines near their optimum viable output performance, manufacturers need to find other ways to enhance levels of production. Optimising and accelerating the flow of materials is one possibility.

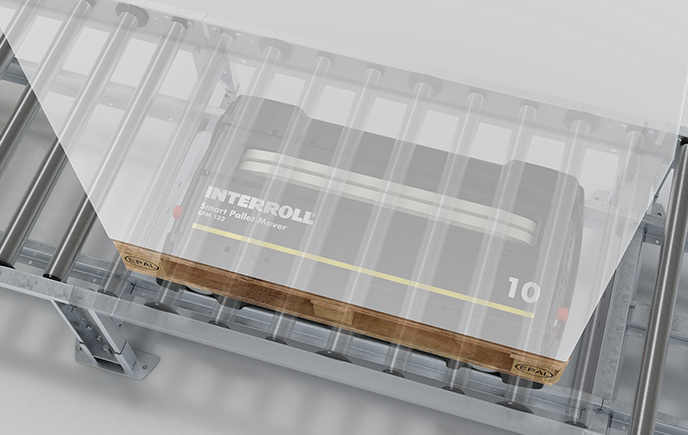

A possibility which the new Smart Pallet Mover from Interroll is designed to make reality.

By focussing efforts on automating work processes in front of machine production, you can benefit in two ways.

Not only are you able to increase productivity, through exploiting the potential of an area of your plant which is generally too little considered. But you are also able to improve workplace safety, by reducing or eliminating manual activities in safety-critical areas.

Both these advantages are a result of utilising the Interroll Smart Pallet Mover for manufacturing logistics. And as its name suggests, it’s not just a smart move for you, but a smart piece of equipment too.

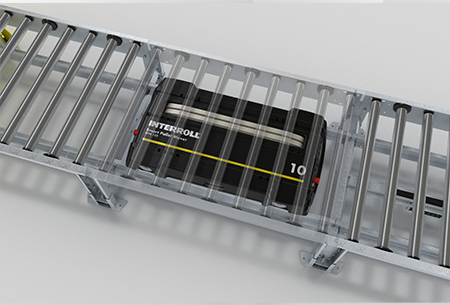

From automating pallet transport around manufacturing machines, to production-related picking and sequencing processes, the capabilities of the Smart Pallet Mover help to automate, accelerate and optimise your production process.

Designed to transport, sort, buffer and sequence pallets and boxes weighing up to 1,000kg, The Smart Pallet Mover efficiently manages your pallet workflow. The result is significantly reduced machine downtime, and increased efficiency of machine production lines or cells.

In fact, by eliminating costly production interruptions of material supply, the Smart Pallet Mover solution has been shown to increase productivity by up to 30% compared to manual operation.

The modular construction of the Smart Pallet Mover helps to make it flexible and scalable. So you can easily adapt it to suit the particular requirements of your production processes.

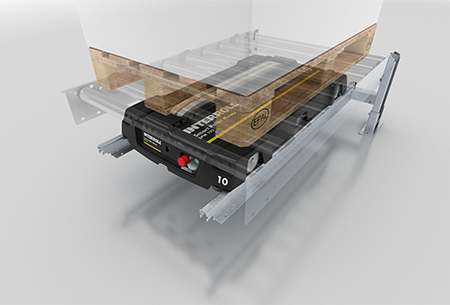

At the heart of the solution is the battery-operated SM1000 Mover mobile unit, which runs underneath non-driven conveyor sections to move the pallets lying on them. Working alongside this unit is the SM2000 Transfer Car, which travels on a rail to transport pallets between parallel conveyor sections.

To prevent collisions with people and objects, the Mover unit is fitted with no fewer than 60 sensors.

The Smart Pallet mover solution is plug-and-play, and easy to install, operate and maintain. Height-adjustable supports mean it can be installed even on uneven floors. And if the needs of your production process change, both modules can easily be reconfigured.

A user-friendly 3D online tool not only helps with configuration of the system, but also simulates planned operation, to make it easy to achieve the most efficient and productive set-up in the least possible time. The solution is fully networkable, using global data standards for maximum compatibility, so it can seamlessly integrate into existing IT environments.

Together, all these features combine to ensure downtime for installation or reconfiguration is always kept to a minimum.

A key element of the Smart Pallet Mover’s construction are the rollers. These are tried and tested components proven for robustness and durability over many years.

And though the solution itself is brand-new, it has already been doubly awarded.

First, it won the internationally-renowned Red Dot Award, Product Design 2021, for its exceptional design quality and degree of innovation. Second, it was chosen by the International Intralogistics and Forklift Truck of the Year Awards as a 2021 Finalist.

But the real rewards come in the manufacturing plant. This is where you can expect to see the Interroll Smart Pallet Mover boost the performance of manufacturing logistics, enhance workplace safety, and increase the level of manufacturing automation: a key factor in optimising efficiency and productivity.

Volatile markets. Products with a high degree of individualisation. Short product lifecycles. Constantly increasing product diversity. Order complexity. Together they’re conspiring to drag your production lines into the slow lane.

But by automating movement of materials, you can get production moving again – and faster than ever. That’s a moving story, with a very happy ending.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000